FY-M1080 Semi-Automatic Thermal Film Laminating Machine is suitable for thermal laminating, with features of easy operation and high flexibility. Widely used in books, books, calendar, card, product samples, packaging carton framed plastic, improving the printing matter grades, and achieve the purpose of dustproof, waterproof, oil proof. It’s the best choice for printing and laminating enterprises of all scales.

Function:

Semi-automatic pre coating laminating machine, the composite processing of paper and pre coating film. This Machine structure is reasonable and easy operation.

Function introduction of each part:

1. Paper Feeding Workbench

The workbench adopts rubber conveying belt transmission, paper feeding way adopt continuous overlap. Workbench with one positioning strip which is used for paper side positioning.

2. Hot-press Roller

The hot press roller adopts six sets of stainless steel U-type heating pipes for heating, the power of each set is 2KW. The inside of the hot roller is filled with 320# conduction oil for heating, the temperature measurer is installed in the shank of the hot roller, the hot roller surface temperature is provided with the electronic regulator for automatic measurement and control.

3. Paper collect rolling part

The paper collect rolling part one is has the single-station rolling and double-station collect rolling for selection.

The double-station rolling has two rolling shafts capable of rolling without stop, it is suitable for thin paper laminating.

The single-station rolling drives the rolling shaft by its mainframe, when processing thick paper, it can be cut directly by labor, it is suitable for thick paper laminating.

4. Cutting part

Cutting part with round (fly) knife device (Independent research and development by our factory), easy adjustment. it is an optional device.

|

|

Specification:

|

Model |

FM-1080 M(with cutting part) |

FM-1080M |

|

Max paper width |

1080mm |

1080mm |

|

Working Speed |

10-30m/min |

10-30m/min |

|

Paper Thickness |

100-500g/m² |

100-500g/m² |

|

Total Power Required |

18kw |

17kw |

|

Electric Power |

12kw |

12kw |

|

Voltage |

380v 50hz |

380v 50hz |

|

Weight |

3300kg |

2300kg |

|

Machine Dimensions |

6000*2000*1600mm |

2000*2000*1600mm |

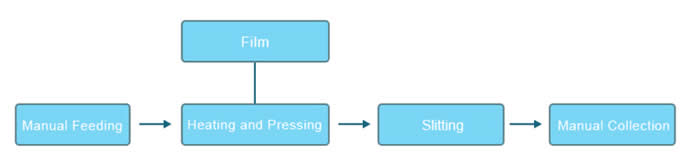

Processing:

Film: Pre-coating Film

Manual Feeding: Paper Feeding

Heating and pressing: Laminating and Paper Collection

Slitting: Cutting

Product Characteristics:

Characteristics:

No glue units, the provincial working procedure, Economical and environmental protection.

No drying tunnel, save electricity, save space.

The machine speed, pressure big, the page width, suitable for all kinds of printed matter.

Hot press roller with an inner oil heating system, high temperature, the temperature effect is good, achieve membrane tectorial quality requirements.

Machine details:

Samples:

|

|

Main Configuration list

|

No. |

Name |

Brand |

Origin |

|

1 |

Main motor |

CHNT |

Shanghai, China |

|

2 |

Transducer |

Delisle |

Wenzhou, China |

|

3 |

Rolling motor |

Shanghe |

Shanghai, China |

|

4 |

Bearing |

NSK |

Japan |

|

5 |

Button |

Schneider |

France |

|

6 |

Breaker |

Schneider |

France |

|

7 |

Electric thermocouple |

Teach |

Shanghai, China |

|

8 |

AC contactor |

Schneider |

France |

|

9 |

Worm gear case |

Zhenyu |

Hangzhou, China |

|

10 |

Hydraulic pump |

Tiandi Hydraulic |

Ningbo, China |

|

11 |

Rotating joint |

Yujie |

Quanzhou, China |

|

12 |

Chain |

Xilin |

Hangzhou, China |

|

13 |

Heating pipe |

Longhui |

Wenzhou, China |

|

14 |

Conveying belt |

Wolsey |

Wenzhou, China |

Enterprise:

Warranty:

Machines are new (or unused) and the guarantee period will be given thirteen months from shipment date. During this period, the seller will provide free maintenance and free spare parts that caused by the machine’s quality, but the buyer must pay the courier cost. Parts damaged because of mishandling and consumable parts are not covered by any warranty. Wages: 80.00USD per day!