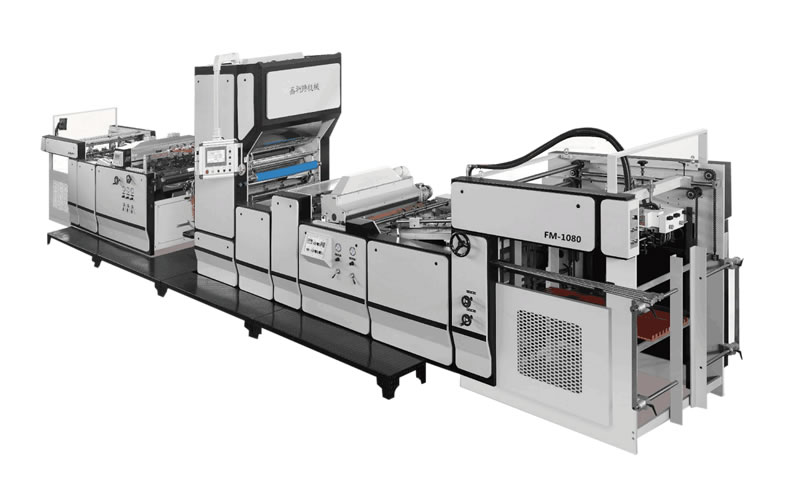

SG-II1200 UV oil coating machine which is suitable for the varnishing and polishing process of various paper, machine for water-based oil, UV oil and blister varnish oil coating, after processing the print surface has the damp-proof and water-proof effects. Machine adopts the reversing mechanism to make the oil layer smooth and fine, save varnish oil and meets the high quality requirements. The coator adopts air knife system which controlled by memory type PLC.

2.The paper feeding table has upper and lower over-limit protection

3.Double or multi-sheet detection device

4.The paper pile table rise protection device, there is a micro switch above the paper carrier to prevent the paper from rising too high and hitting the feeder

2.The metering rollers are individually motor driven to ensure even gluing.

3.Add pedal for workers to step on and use, more convenient to debug the machine, and add railing behind the pedal for more safety.

4.Improved air knife technology for thin paper (100-600g) to ensure that the paper does not attach to the roller after coating and runs smoothly.

5.Upgrade the touch screen operation center console, more convenient and accurate operation.

2.Fan cooling device

2.The metering rollers are individually motor driven to ensure even gluing.

3.Add pedal for workers to step on and use, more convenient to debug the machine, and add railing behind the pedal for more safety.

4.Improved air knife technology for thin paper (100-600g) to ensure that the paper does not attach to the roller after coating and runs smoothly.

5.Upgrade the touch screen operation center console, more convenient and accurate operation.

1.Ultraviolet drying with 3pcs ultraviolet lamp

2.Fan cooling device

2.Counting electric eye, the number of running paper is displayed on the display screen at the take-up machine, which can be cleared and accumulated

3.Induction electric eye, sensing the length of the paper, if the length of the paper changes, the belt will accelerate, and the baffle of the take-up machine will overturn and lift the paper