2. Water Dust Remover (optional)

3. UV coator/ Water base oil coator

4. IR and UV dry

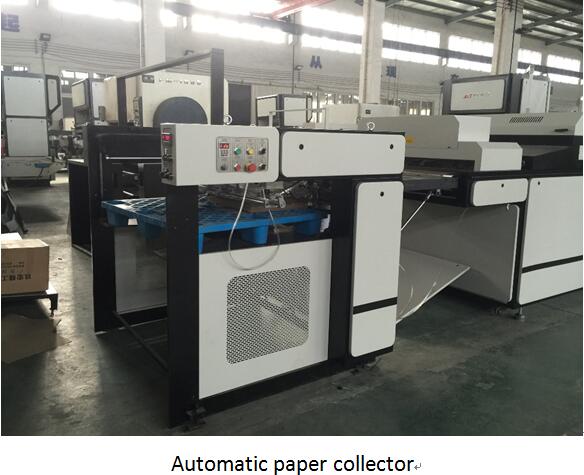

5. Automatic Collector

Usage:

It is a paper surface varnishing (UV) and polishing machine which is suitable for the varnishing and polishing process of various paper (80-600g/m²); various paper prints after processing greatly improve surface gloss; the print surface has the damp-proof and water-proof effects. The machine adopts the reversing mechanism to make the oil layer thinner and more even.

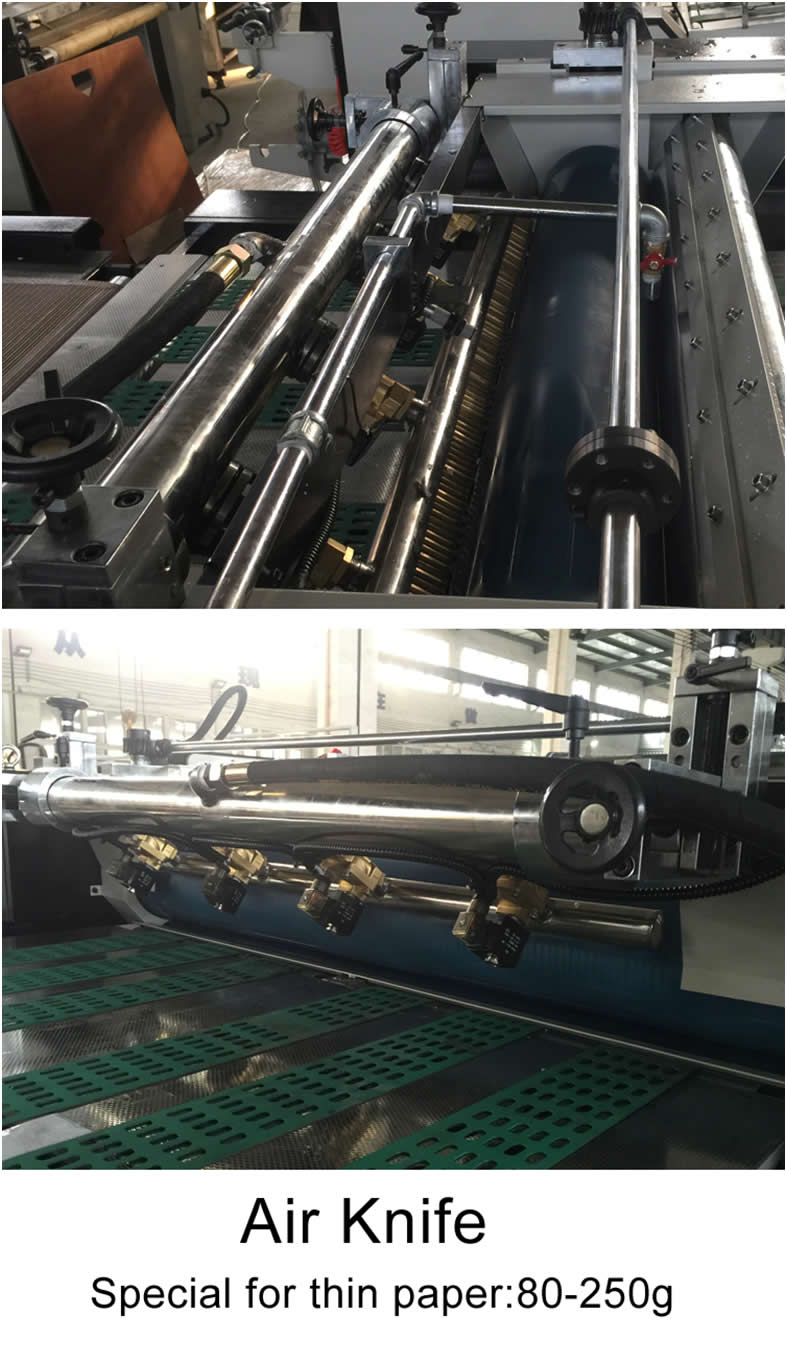

The machine also adopts a computer air knife device, a strong absorption mechanism and a right-and-right scraper transmission mechanism. It has the characteristics of beautiful appearance, stable and reliable performance, simple and convenient operation and high automation degree.

Function introduction of each part:

Automatic paper feeder:

The automatic paper feeder has the function of pre-piling paper to guarantee coherent and stable conveying.

Polishing and varnishing head:

The head adopts a three-roller reversal speed control head to guarantee aqueous polishing effect and no stripe mark; the metering roller is driven by the independent motor so as to ensure even gumming amount. The air knife device can be used for the paper less than 250g.

Drying part:

The infrared drying tunnel adopts 18 infrared tubes with 1.2Kw per piece. The ultraviolet drying tunnel adopts 3 ultraviolet tubes with 8Kw per piece. The inside of the drying oven adopts a UV automatic deviation-correcting device in high precision. The automatic temperature controller of infrared lamps has stable temperature. The more reasonable drying and cooling system with fan for assistance ensures the aqueous varnishing and drying effects; the infrared lamp and UV (ultraviolent) drying oven has an automatic rising-lowering protector.

Automatic paper collector:

The automatic paper collector pats paper right and left to ensure paper collection in order without shutdown.

Main Technical Parameters:

|

Model |

SE-1200 Manual |

SE-1200 Automatic |

|

Length of Roller |

1250mm |

1250mm |

|

Max. paper size |

1150 |

1150*900mm |

|

Min. paper size |

* |

390*320mm |

|

Paper Thickness |

80-600g/m² |

80-600g/m² |

|

Working speed |

80m/min |

80m/min |

|

Voltage |

380v 50Hz |

380V 50Hz |

|

Motor Power |

2.5kw |

3.5kw |

|

Total power |

65kw |

70kw |

|

Infrared Heating Power |

18kw (15 pcs*1.2kw) |

18kw (15 pcs*1.2kw) |

|

Ultraviolet Heating Power |

24kw (3 groups*8kw) |

24kw (3 groups*8kw) |

|

Machine Weight |

3000kg |

4500kg |

|

Overall Dimension |

9800*2000*1600mm |

11800*2000*1800mm |

|

Package |

Seaworthy packing |

Seaworthy packing |

|

Loading |

40” container |

40” container |

Remark: accept customization of equipment in various specifications

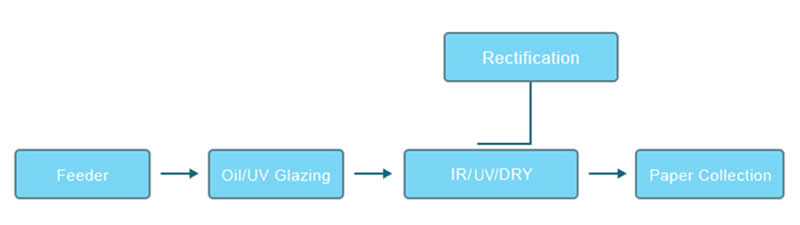

Processing line:

Product Characteristics:

The product has the functions of automatic paper feeding and collection, has rapid printing speed and improves the productivity effect.

The inside of the drying oven adopts a UV automatic skew detection mechanism in high precision.

The reasonable fan cooling system ensures aqueous varnishing and drying effects.

Three-roller reversal head guarantees no stripe mark.

The machine has industrial aesthetics design, beautiful and elegant appearance, scientific structure and stable performance.

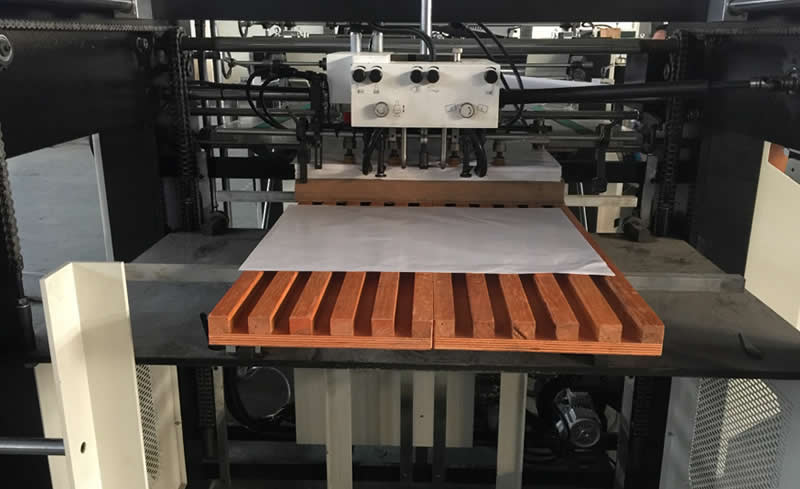

Machine main part image:

Automatic paper feeding-feeder

Detailed list of main parts

|

No. |

Name |

Brand |

Origin |

|

1 |

main motor |

Gongtai |

Shanghai |

|

2 |

vacuum pump |

Tongyou |

Jiangsu |

|

3 |

Feeder |

Runze |

Zhuji |

|

4 |

transducer |

Delta |

Taiwan |

|

5 |

gum pump |

Lishao |

Shanghai |

|

6 |

Draught fan |

Yinniu |

Taizhou |

|

7 |

Air cylinder |

AIRTAC |

Taiwan |

|

8 |

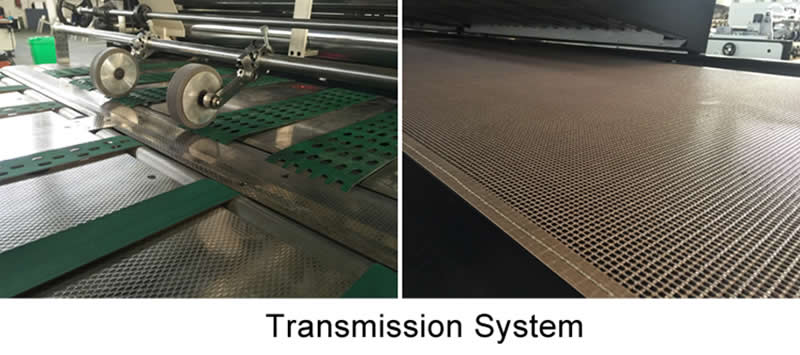

conveying mesh belt |

USAUS |

Jiangsu |

|

9 |

Bearing |

NSK |

Japan |

|

10 |

Button |

Schneider |

Germany |

|

11 |

AC contactor |

Schneider |

France |

|

12 |

Breaker |

CHNT |

Wenzhou |

|

13 |

Relay |

Schneider |

France |

|

14 |

Transformer |

Xingyiyuan |

Beijing |

|

15 |

UV lamp |

Xingyiyuan |

Beijing |

|

16 |

switch power supply |

Delta |

Taiwan |

|

17 |

optoelectronic switch |

Teach |

Shanghai |

|

18 |

temperature controller |

WINPARK |

Jiangsu |

|

19 |

Bearing |

NSK |

Japan |

|

20 |

Electronic counter |

Dahua |

Wenzhou |

|

21 |

touch screen |

Delta |

Taiwan |

|

22 |

encoder |

Omron |

Japan |

|

23 |

optical fiber sensor |

Omron |

Japan |

|

24 |

thermoelectric couple |

Teach |

Shanghai |

|

25 |

PLC |

Julong |

Shanghai |

|

26 |

Capacitor |

Xingyiyuan |

Beijing |

Enterprise Brief:

Warranty:

Machines are new (or unused) and the guarantee period will be given thirteen months from shipment date. During this period, the seller will provide free maintenance and free spare parts that caused by the machine’s quality, but the buyer must pay the courier cost. Parts damaged because of mishandling and consumable parts are not covered by any warranty. Wages: 80.00USD per day!