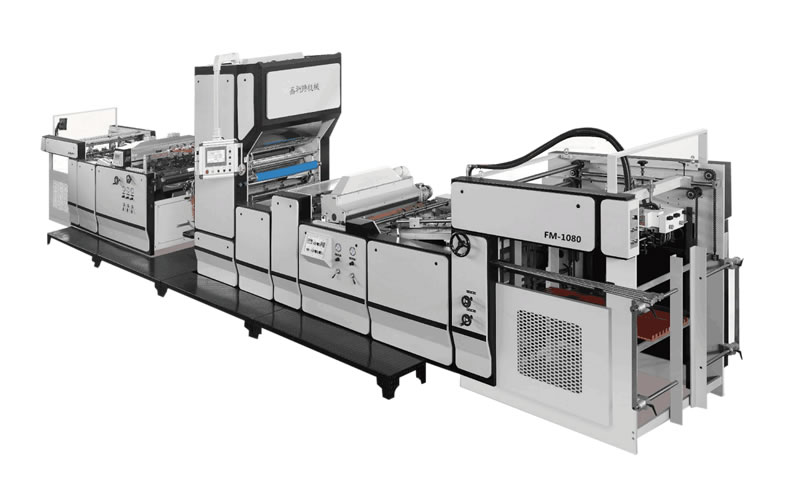

FM-E fully Automatic Vertical High-precision and multi-duty laminator as a professional equipment used for plastic film laminating on the surface of paper printed matter. Widely applicable for laminating in packaging, paper box, books, magazines, calendars, and commercial cards fields, Improving the printing matter grades, and achieve the purpose of dustproof, waterproof, oil proof. it’s the best choice for printing and laminating enterprises of all scales.

FEEDING UNIT

1.4 suckers for lifting and 4 suckers for conveying structure. Max Speed 12000 sheets/h

2.The paper feeding table has upper and lower over-limit protection

3.The height of non-stop feeding can reach 1150mm, pre-stacking device, non-stop feeding

CONVEYING TABLE AND OVERLAP

1.The conveying table adopts customized stainless steel corrugated board

2.The brush wheel and rubber pressing wheel move smoothly

3.Servo motor overlap, improve accuracy of lap, error≤±2mm

LAMINATOR HOST

1.Glue roller and metering roller are driven by dual independent motors, making adjustment more convenient

2.Drying roller diameter increased to 800mm, using electromagnetic heating system.

3.Max pressure of press roller is 12T

4.Gluing system Teflon process treatment, easy to clean and non-sticky

DOUBLE HEATING ROLLER UNIT(OPTIONAL)

Second heating pressure make the paper surface more bright and improve the product quality. Specialized use for the dark printing products laminate processing, after second heating pressure, the product surface without white dots. Dark glue laminating will choose this unit.

CUTTING UNIT

1.The paper cutter is equipped with a tension controller and an anti-curl device to ensure that the paper is flat and not curled.

2.The paper cutting part contains grinding wheel, disc knife and chain knife for slitting, meeting customers' requirements for slitting films of different materials

3.The bounce roller is controlled by an independent motor, and the paper can be separated by using the speed difference

NON-STOP COLLECTOR

1.Adopt pneumatic paper sorting structure to ensure the neatness of the paper and facilitate the next process

2.Counting electric eye, the number of running paper is displayed on the display screen at the take-up machine, which can be cleared and accumulated

3.Induction electric eye, sensing the length of the paper, if the length of the paper changes, the belt will accelerate, and the baffle of the take-up machine will overturn and lift the paper